STORAGE

Square meters

Cubic meters

Tons

A separate storage location for each delivery

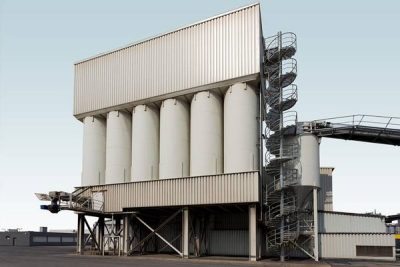

We have plenty of space on our site in Hamm:

We can store on about 20,000 m² with a capacity of over 40,000 t. In addition, approx. 1000 t storage capacity is available in silos for finished product.

PROCESSING

DRYING

DEDUSTING

COOLING

SIEVING

In the best quality

Drying, dedusting, cooling and sieving are used in our processing plant.

The different chrome ore sands are exclusively produced in separate silos. With our modern PLC controlled system, we can efficiently reduce fine fraction.

PACKAGING

LOOSE SILO MATERIAL

PAPER BAG,

BIG BAG Whole

ACCORDING TO YOUR NEEDS

READY FOR TRANSPORT

Our products allow us a high degree of flexibility when it comes to packaging and transport. Our chrome ore sand can be loosely filled directly into silo trucks or packed in paper bags or big bags for transport.

Are you looking for an individual packaging and transport solution?

Together we will find a way.

CARGO SECURING

BECAUSE IT IS BETTER

TO BE SAFE THAN SORRY

COMPLIANT AND DOCUMENTED

Every load that leaves our site is compliant and properly documented secured for transport.

In doing so, we act according to our operating instructions for the safe loading of finished products (download PDF).

QUALITY ASSURANCE

CONTROLS – ROCK HARD AND CERTIFIED

Certified quality management

You have high requirements on our product – and justifiably so.

In order to meet these requirements, we have established a certified quality management system in accordance with DIN EN ISO 9001:2015.

We’ll give this to you in writing:

Download the certificate as PDF in English

Download the certificate as PDF in German

TRUST IS GOOD

CONTROL

IS BETTER

Constant checks

All materials, both raw materials and processed products, are precisely controlled in the company’s own modern chemical testing laboratory. This ensures that customer specifications and standards are met. The laboratory produces chemical analyses using x-ray fluorescence analysis (XRF)technology. In addition, we can also identify other important material properties in the industry such as bulk density,bulk weight, acid consumption, pH value, etc.

At HAG all raw materials are subject to an incoming analysis at entry into storage. The sieving laboratory is available 24 hours a day for production control. There, grit distributions are determined. It’s better to be safe than sorry. The test laboratory ensures the consistently high quality of the products. If desired, customers can have this confirmed with a letter and seal.

- Lagerung im Silo

- Aufbereitung – Befüllung AnlageAufbereitung – Befüllung Anlage

- Aufbereitung – Förderband

- Aufbereitung – Siebanlage

- Aufbereitung – EDV

- Verpackung – Abfüllung Siloware

- Verpackung – Abfüllung in BigBags

- Verpackung – BigBags

- Verpackung – Abfüllung in Papiersäcke

- Verpackung – Papiersäcke

- Verpackung – Kundenwunsch

- Analyse – Probennahme

- Glühverlustbestimmung

- Schmelztablette für RFA

- Chemische Analyse mit der RFA (Röntgenfluoreszenzanalyse)

- Internationale Standards zur Kalibrierung der RFA